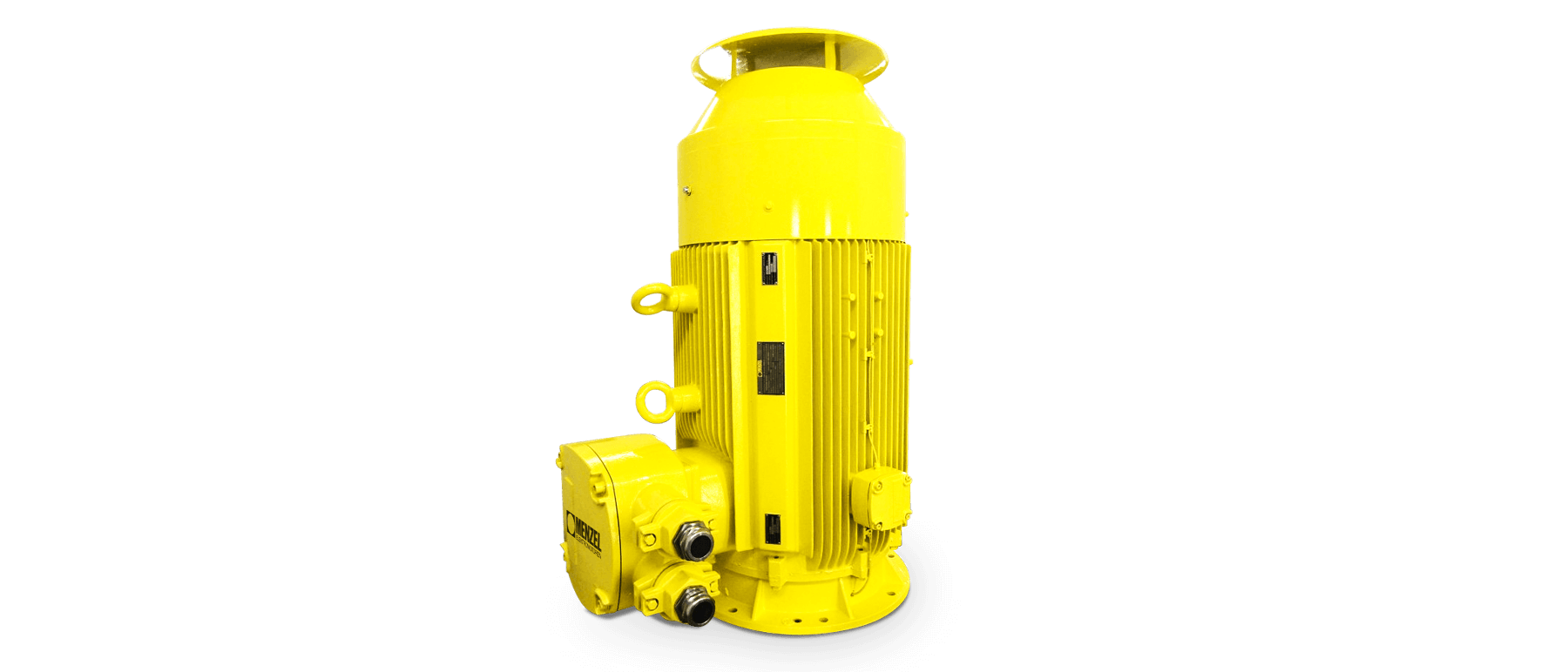

Pressurized Ex p motors for operation in zone 1

MENZEL has been certified for the production of large squirrel-cage motors in hazardous areas with ignition protection type Ex p pressurization for operation in zone 1 hazardous areas where an explosive gas/air mixture is likely to occur in normal operation.

MENZEL can apply this manufacturing procedure to pre-engineered stock motors in a wide output range and is thus able to flexibly and quickly provide competitively priced Ex p motors featuring the product categories 2G and 3G. Pressurized motor construction is typically suitable for squirrel-cage motors from 400 mm shaft height.

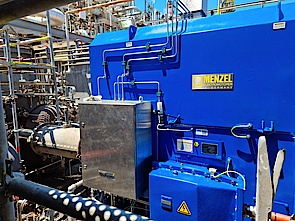

Menzel Elektromotoren has been certified for the production of large squirrel-cage motors in ignition protection type Ex p pressurization for operation in zone 1 hazardous areas where an explosive gas/air mixture is likely to occur in normal operation. The test specimen, a compressor motor for the petroleum industry, underwent a gas displacement test (test of the air purge system), leak test and pressure test. The German technical inspection service TÜV Nord comprehensively tested and certified the construction method. To win the approval, the manufacturer had to prove its ability to control the purging air flow for all its relevant motor series in such a way that no gas pockets remain inside the motor casing.

Motors in ignition protection type Ex p pressurization from 400 mm shaft height

Pressurized motor construction is typically suitable for squirrel-cage motors from 400 mm shaft height. It is available for all voltage ranges and with air-to-air or air-to-water heat exchangers (cooling types IC 611, IC 616 or IC 81W).

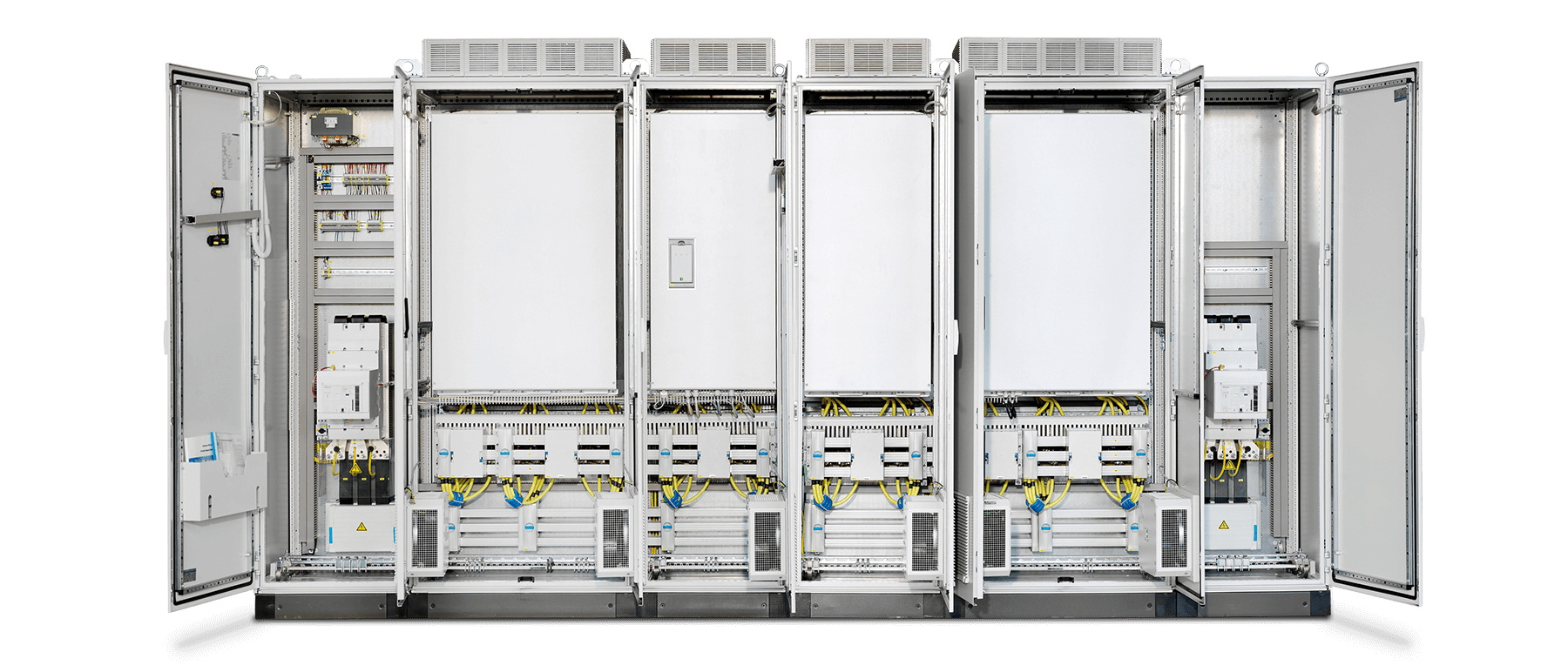

An air-purge system allows potentially flammable gases to be removed from the motor frame before the motor is started and to maintain a constant positive pressure during operation to prevent the ingress of explosive gases. The terminal boxes feature the ignition protection type Ex eb increased safety.

Our ATEX II 2G Ex pxb ec IIC T3 Gb motor offer

- Temperature classes: T1, T2, T3 up to 200°C

- Power range: up to 25,000 kW

- Voltages: up to 13.8 kV (for 50 and 60 Hz)

- Common designs: IM B3, IM B5, IM V1, IM B35

- Frame size: from 400 mm

- Cooling classes: Air-to-air or air-to-water cooling (CACA or CACW)

MENZEL offers:

- Calculation and design of the purge system

- Planning and design of the air distribution in the motor

- Installation and configuration of the purge system

- ExP terminal boxes including the option of mounting the terminal boxes horizontally

- Special coating in accordance with the prescribed paint coating thickness of 200µm (for IIC)

- Special grooved thermometers with Ex approval

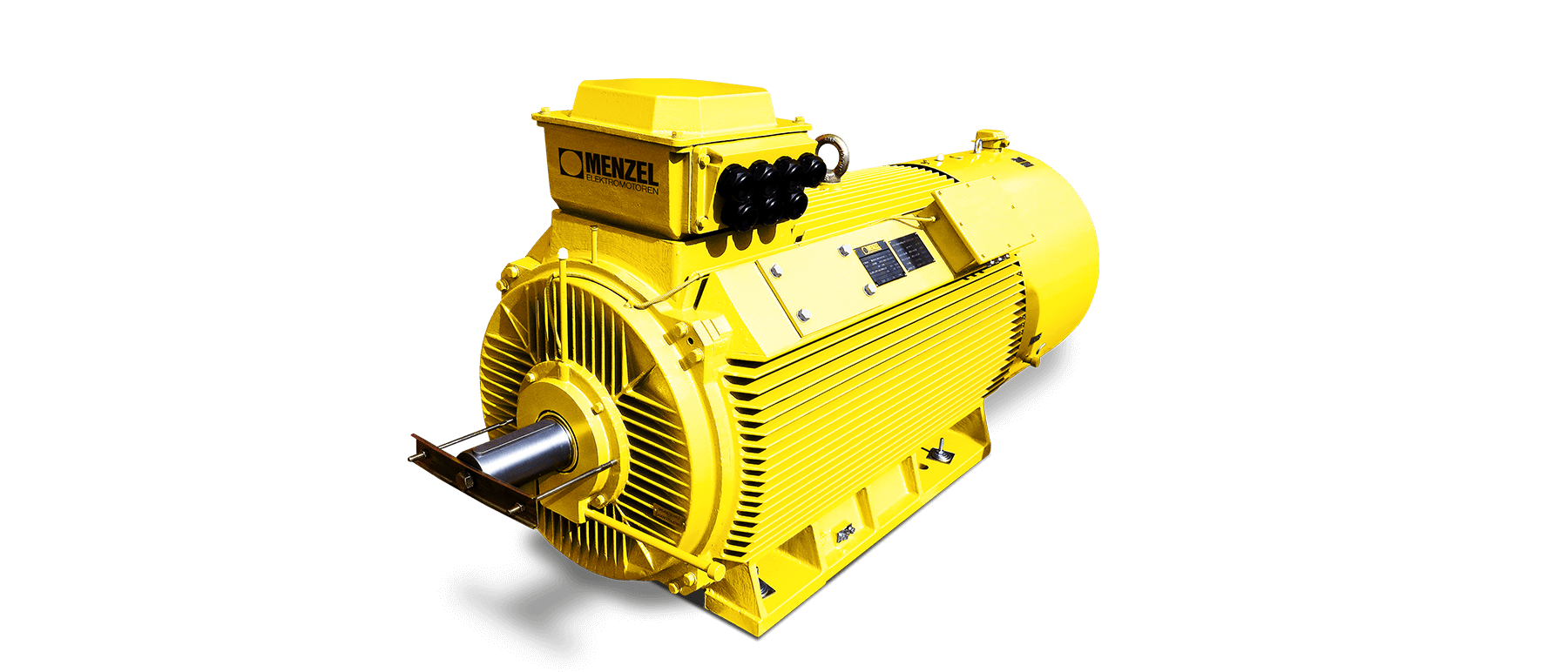

MENZEL won Product of the Year Award

MENZEL's pressurized EXP motors for zone 1 allow large modular motor operation in Zone 1 CACA or CACW, from 400mm frames and larger at all voltage ratings. Like all our squirrel cage motors, these motors are built to site requirements and to the highest safety standards. Specifically used by customers operating larger motors in hazardous areas like refineries and chemical plants, as well as for applications in the oil and gas industry.

We are proud that this particular motor solution which has recently been awarded with an important industry award: MENZEL won the ‘Product of the Year Award’ with its pressurized EXP motors for zone 1 by the The UK's Association of Electrical & Mechanical Trades.

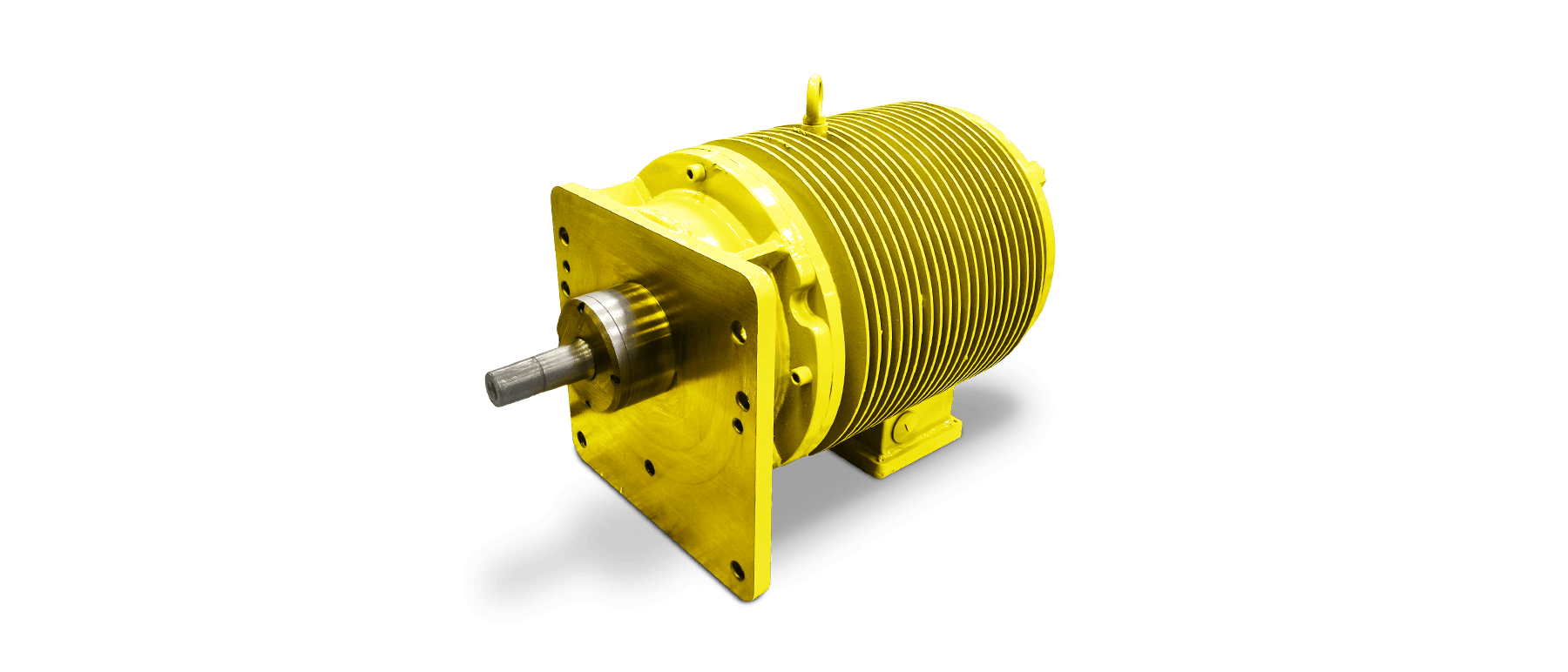

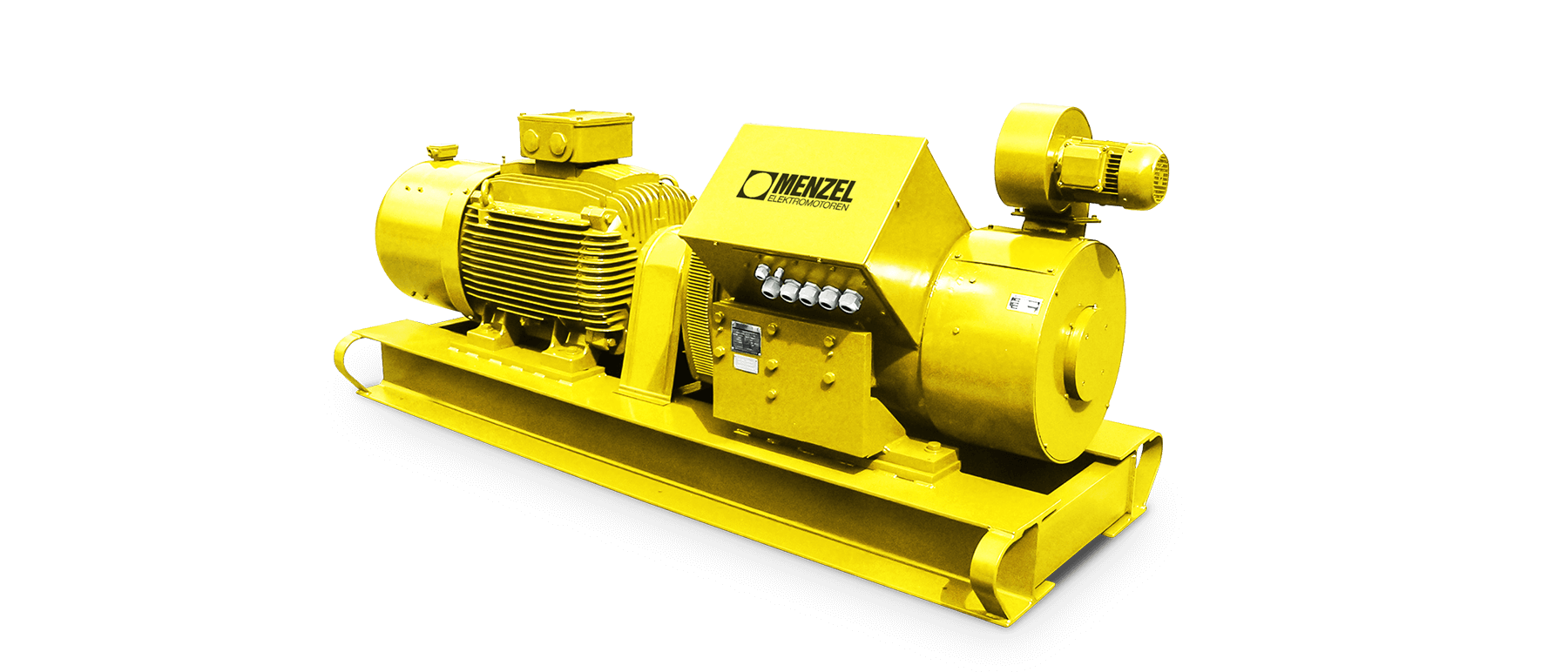

6000 V Ex p compressor motor for huge Italian petrochemical company

For one of Italians biggest petrochemical companies, Menzel has recently manufactured an Ex p compressor motor based on its MEBKSL series, which matches the original motor in all mechanical and electrical interfaces. Before shipping, the motor was rigorously tested in the company's inhouse test facility, including load and type testing.

- Three-phase asynchronous motor Type: MEBKSLP500-04

- Operation mode: S1

- Rated power: 1635 kW

- Voltage: 6000 V

- Power factor: 0,89

- Speed: 1488 min-1

- Mounting: IM 1001 (IMB 3)

- Frequency: 50 Hz

- Protection class: IP 55

- Cooling class: IC 611 (air-to-air heat exchangers)

- Thermal class: F

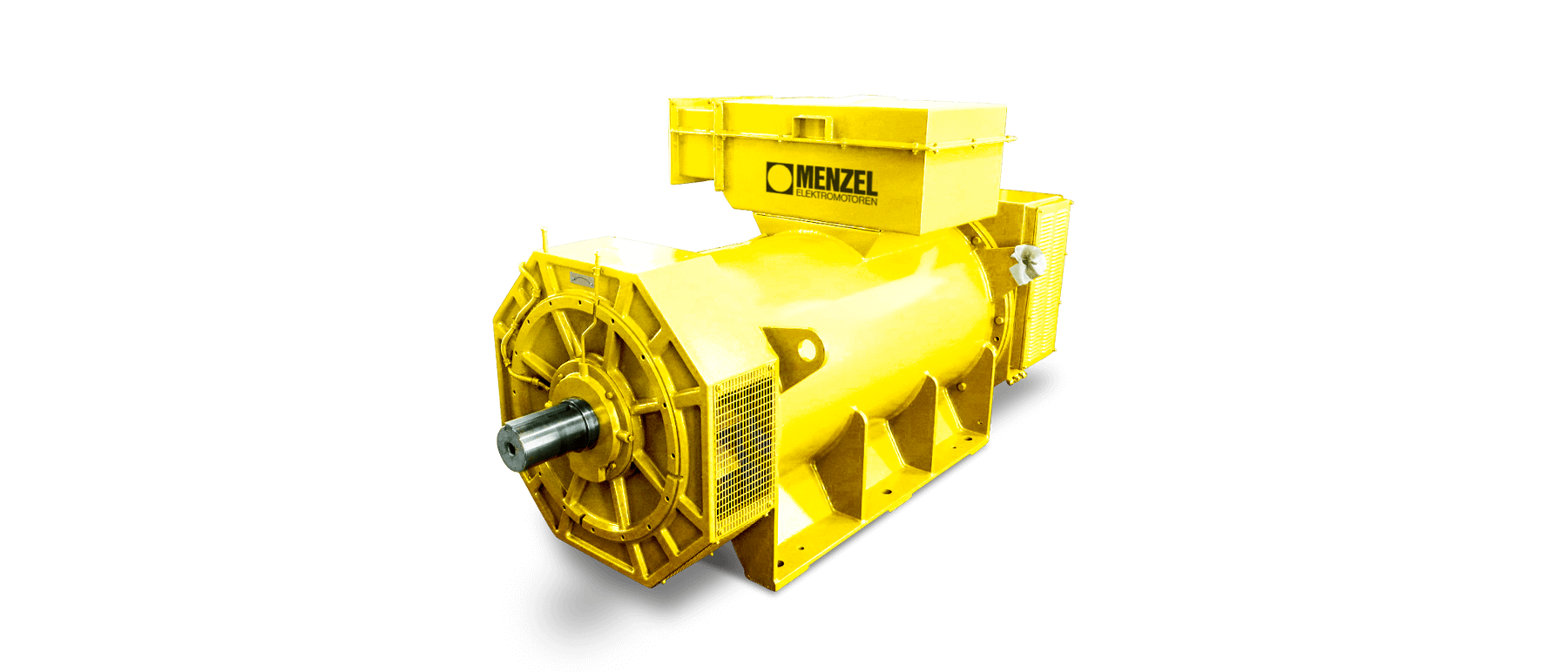

Customer benefit: Freedom of choice and flexibility

Plant operators often face the challenge that they cannot find suitable replacements for obsolete motors. The choice of explosion-proof drive systems in particular is limited. Up until now, the only alternative was to buy a standard motor with the required explosion-protection rating and adapt the installation site and/or driven machine, sometimes at considerable time and expense. MENZEL’s certification for the construction and manufacture of protected motors now gives customers more freedom of choice and flexibility.

MENZEL is specializing in large electric motors and always configures motors for the individual application and installation conditions. Likewise, the air purge system for pressurized motors is individually calculated and implemented, ensuring that the finished systems meet the highest safety standards.

Our highly qualified staff ensure that we can respond to your inquiries within the shortest possible time. MENZEL can apply the certified manufacturing procedure to stock motors in a wide output range and is thus able to flexibly meet your needs.

MENZEL Ex p motors – the advantages at a glance:

Optimal level of efficiency

Optimal safety

Energy efficiency

Robust housing

Operational safety

Serviceability

Can be delivered directly from the warehouse in the event of an emergency

Are you looking for an pressurized motor constructionEx p for operation in zone 1? We have the right motor for you!